Search

en

- Home

-

Products

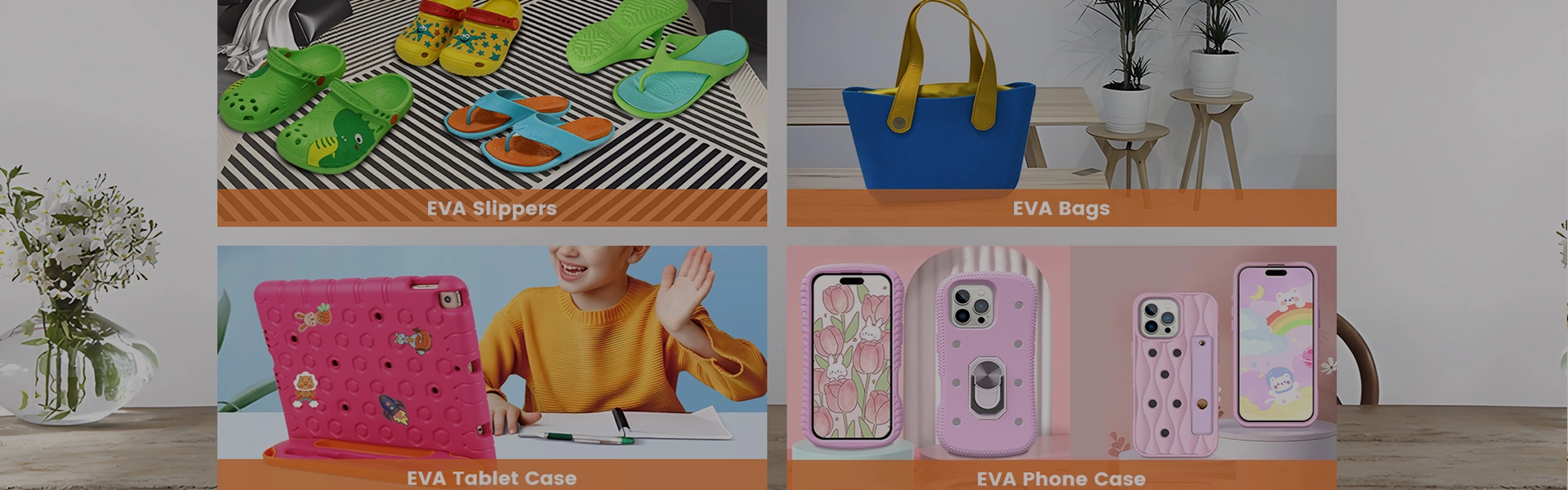

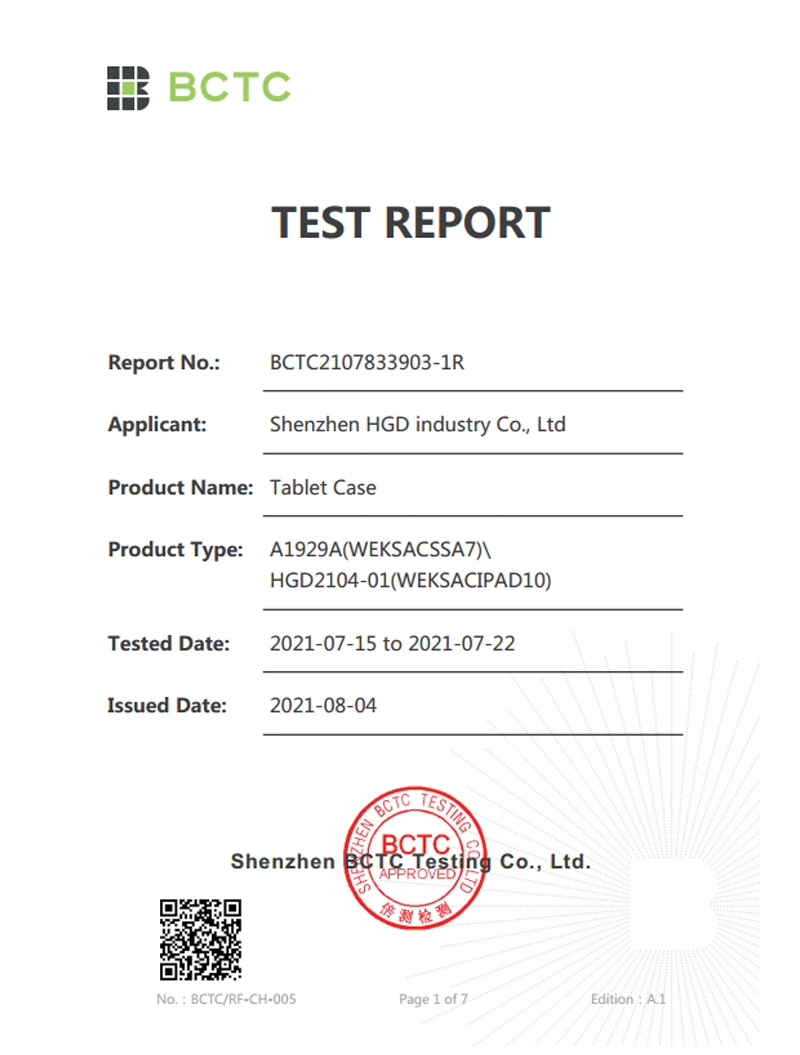

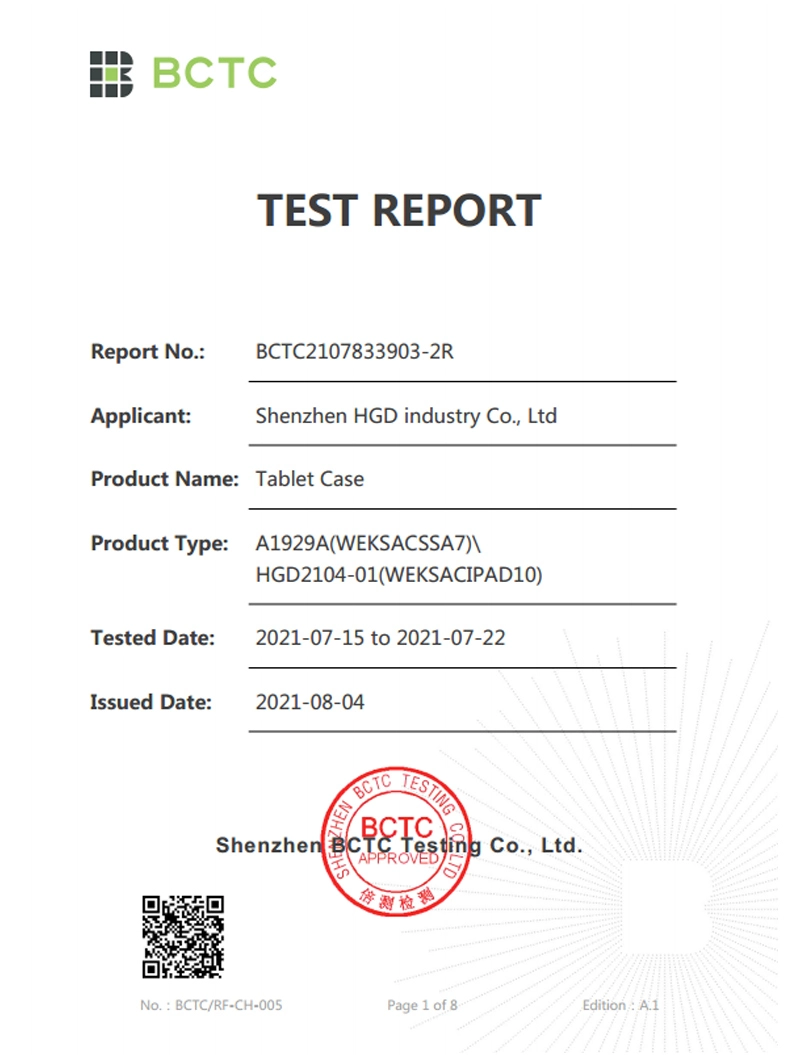

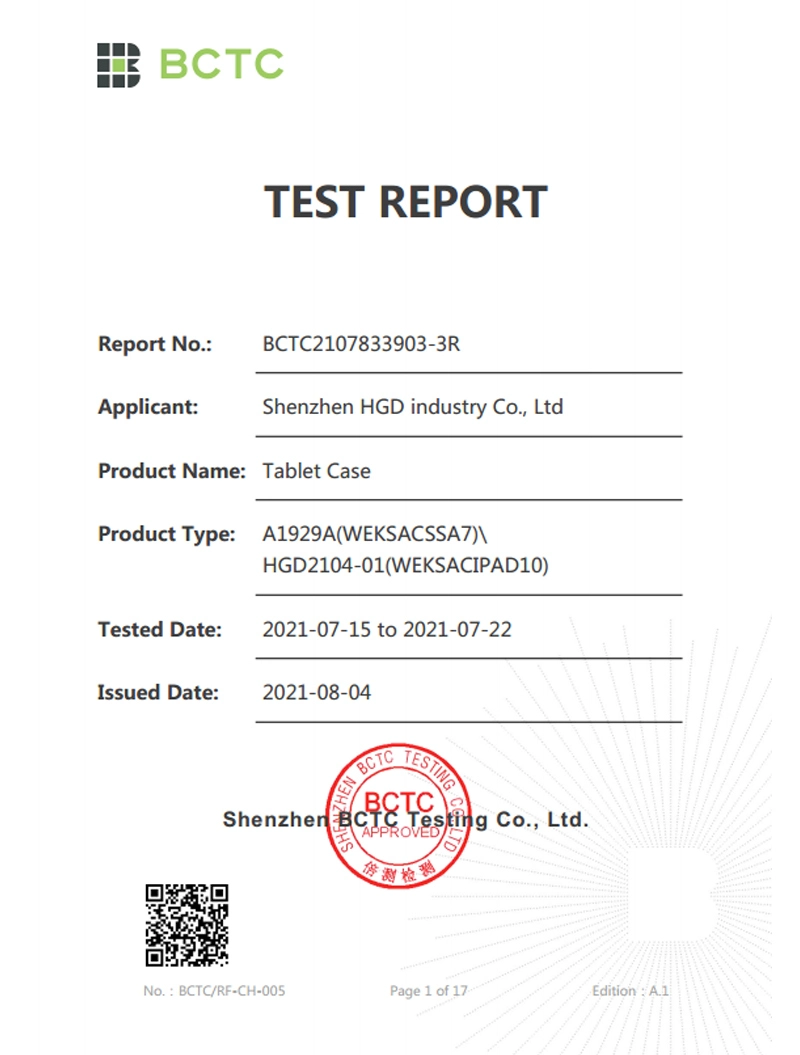

iPad Pro 11''1/2/3/4A1133-103 iPad Pro 11''1/2/3/4 Case A1133-2102 iPad Pro 11''1/2/3/4 Cover Case for iPad (A16) 11th Generation 11 Inch 2025-IPad 10th Generation 10.9 Inch 2023,Heavy Duty Shockproof Rugged Protective Case Customizable Rugged Full Body Protective Cover for Xiaomi Apple IPad 11 Inch A1133-115 iPad Pro 11''1/2/3/4 Case A1133-116 iPad Pro 11''1/2/3/4 Case A1133-117 iPad Pro 11''1/2/3/4 CaseLG Pad IV 8.0 FHD (2017)HGD2108 LG Pad IV 8.0 FHD (2017) Case Kids Friendly Tablet Cases for IPad 11th A16 10th Gen 10.9'' 2022 Heavy Duty Kickstand Cover EVA Foam Tablet Covers Case for iPad Air 3/Pro 10.5 11 inch Kickstand Handle Eva foam Tablet Case for Ipad 10 10.9 Inch 2022 With Pen Slot Wholesale customized Shockproof Rugged Tab Custom Protective Heavy Duty Tablet Case Cover for Ipad 11inch Tablet Case for Ipad 10th Generation 2022 10.9 Rugged Case With Hand Strap Japanese Korean Wind Shell Multi-Functional Protective Cover for iPad 10 11 inch(2022/2025) Tablet Cover in EVA Material

- Customized Process

English

English.webp)